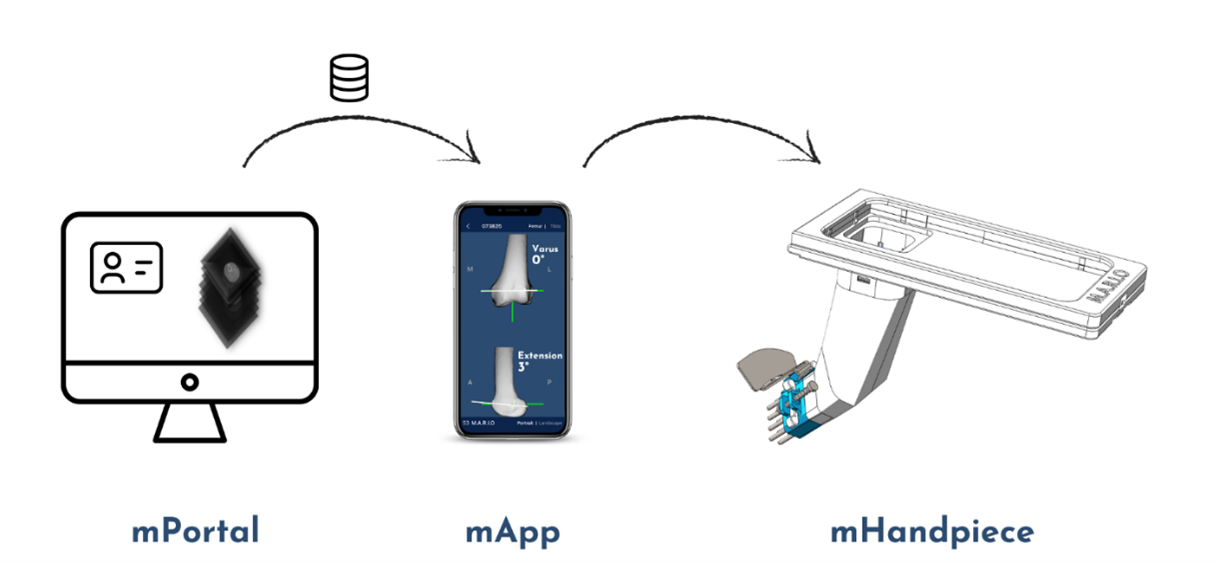

M.A.R.I.O is a cutting-edge platform technology designed for seamless surgical navigation. Once the patient's

medical

image is uploaded to our portal, we take care of everything—including image processing and navigation model

training.

The user simply needs to load the prepared model onto their smartphone just before surgery. During the

procedure, they

can effortlessly follow on-screen guidance to determine the optimal pin placement for securing the standard

cutting jig.

With no waiting time, a hassle-free workflow, and complete flexibility, M.A.R.I.O streamlines the surgical

process like

never before.

Key Features of M.A.R.I.O

The M.A.R.I.O system offers a cutting-edge, cost-effective solution with numerous advantages that enhance

both

surgical efficiency and accessibility:

- Intra-operative Flexibility: M.A.R.I.O provides unparalleled flexibility during surgery,

adapting to various procedural requirements.

- Affordability and Accessibility: Offering a cost-effective alternative to expensive

robotic

systems and patient-specific instrumentation, M.A.R.I.O. increases accessibility to high-quality care

globally.

- Universal Compatibility: By utilising standard smartphones, M.A.R.I.O ensures seamless

integration with existing healthcare infrastructures, making it accessible to a wide range of medical

facilities.

- Real-time Ligament Balancing: Incorporating real-time ligament balancing, M.A.R.I.O

addresses

a critical gap in low-cost navigation technologies, optimizing alignment during procedures.

- Improved Surgical Outcomes: M.A.R.I.O. enhances alignment accuracy and ligament

balancing,

contributing to better surgical outcomes, reducing complications, and potentially lowering the need for

costly

revision surgeries.

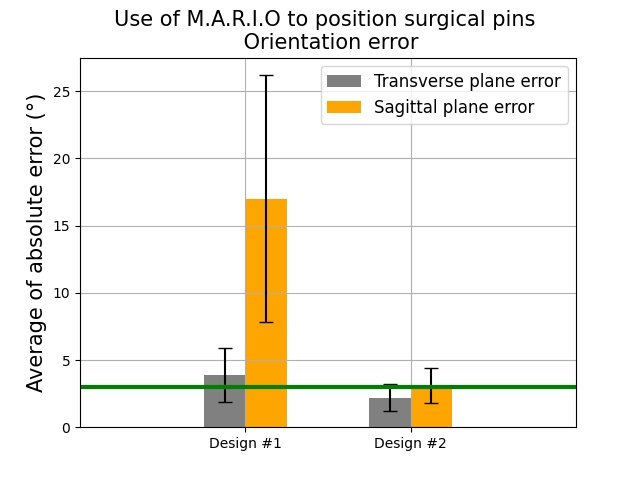

We have implemented a robust testing protocol and conducted

usability assessments involving surgeons using device design #1.

Participants provided valuable feedback through questionnaires, as

outlined in our testing methodology. Both average location and

angular errors exceeded clinically acceptable thresholds, set at 3

mm for location and 3° for angular error. This real-world usage and

feedback collection process unveiled key insights.

During these usability assessments, it became evident that the pilot

holes designed for the installation of referential pins in design #1

were too loose, causing difficulties for the participants during the

surgery. In response to this feedback, we made substantial

improvements in our design approach, leading to the development of

design #2.

The results obtained with design #2 demonstrated remarkable

improvements in performance compared to design #1. Errors in

location and angular measurements consistently fell below the

clinically acceptable thresholds, with significantly reduced

variations between data points. Notably, location errors

consistently remained below the 3 mm threshold, aligning with

clinically accepted standards. While the sagittal plane exhibited

slightly larger errors compared to the transverse plane, the overall

average error remained within acceptable clinical limits.

Our rigorous laboratory validation process conclusively affirms

the efficacy of the M.A.R.I.O device. Its capacity to achieve

implant alignment with remarkable accuracy has the potential to

revolutionise total knee arthroplasty procedures, offering the

prospect of reduced complications and improved patient well-being.

This technology stands as a game-changer in the field, enhancing

surgical outcomes and marking a significant advancement in

orthopaedic care.